Transforming Wastewater from Battery Factories into Raw Materials: Aepnus Technology's Solution

Introduction

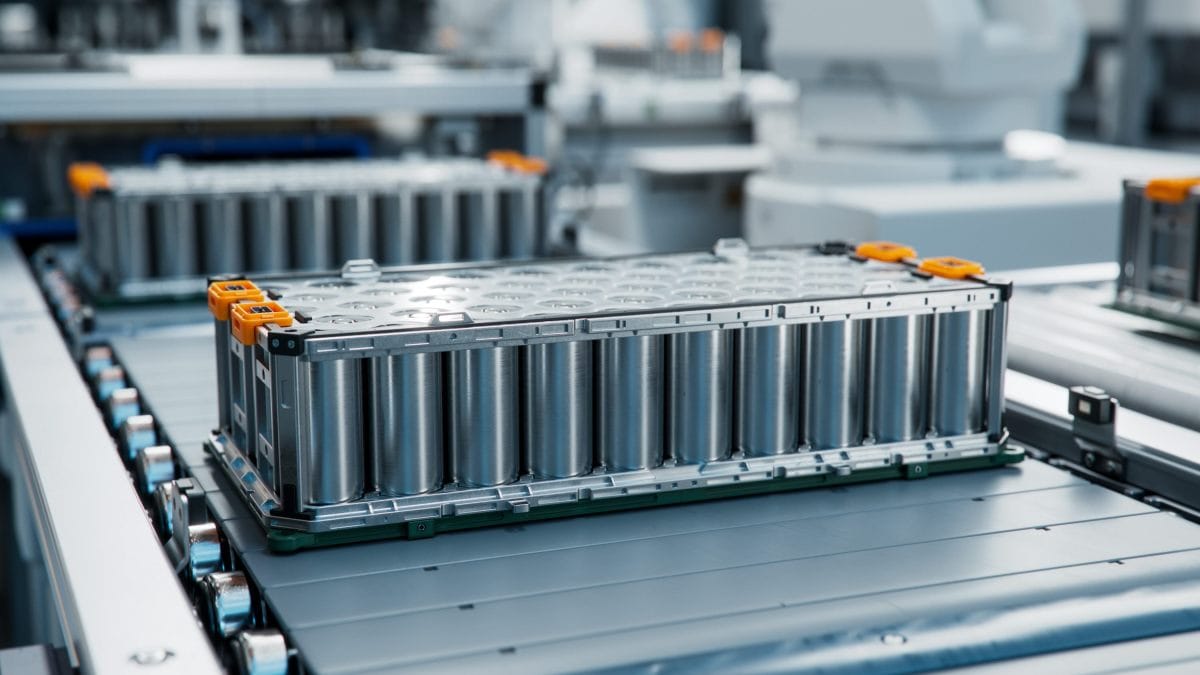

In recent years, the expansion of battery factories around the world has raised concerns about the management of wastewater produced during the manufacturing process. Traditional disposal methods have proven to be unsustainable and environmentally harmful. However, a promising solution has emerged in the form of recycling the wastewater to create a circular economy. Aepnus Technology, a startup founded by Bilen Akuzum and Lukas Hackl, has developed a unique approach to turn waste products from battery manufacturing into valuable raw materials.

The Problem of Wastewater in Battery Manufacturing

Battery factories often generate wastewater laden with sodium sulfate, a by-product of chemicals like sulfuric acid and caustic soda used in the manufacturing process. Disposing of this wastewater has posed a challenge for many companies, leading to delays in plant openings and environmental concerns.

Aepnus Technology's Innovative Approach

Akuzum and Hackl, while initially exploring ideas in the minerals space, discovered the untapped potential of recycling waste products from industrial operations. They set out to modernize the century-old chloralkali process to efficiently split salts like sodium sulfate back into the acids and bases that created them. By using electrolyzers, Aepnus eliminates the need for expensive catalysts, making the process more cost-effective and environmentally friendly.

The Technology in Action

Aepnus is currently providing half-scale models of its equipment to customers, allowing them to test the devices on their wastewater streams. Each site's wastewater may contain different contaminants that need to be filtered before the electrolyzers can effectively remove the sodium sulfate. By fully recycling this waste product, customers can reduce disposal and material costs, as well as save on transportation for remote sites like mining operations.

Business Expansion and Funding

With over 15 customers at various stages of implementation, Aepnus recently secured an $8 million seed round to scale up production and develop commercial-scale electrolyzers. The funding round was led by Clean Energy Ventures and included participation from other climate-focused investors. If Aepnus successfully commercializes its electrolyzers, it would not only revolutionize waste management in the battery industry but also make a significant impact on sustainability efforts in the United States.

Conclusion

Aepnus Technology's innovative approach to recycling wastewater from battery factories represents a significant step towards creating a more sustainable and circular economy. By transforming waste products into valuable raw materials, the company is not only addressing environmental concerns but also offering a cost-effective solution for industrial operations worldwide. With continued growth and support from investors, Aepnus is poised to revolutionize the way we manage waste in the manufacturing sector.